SOURCE: IDRW.ORG

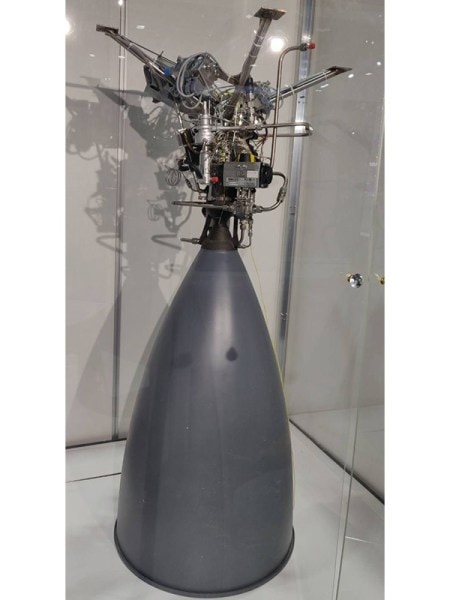

In a remarkable feat, Agnikul Cosmos, an IIT Madras-incubated startup, has launched the world’s first single-piece rocket with a 3D-printed engine. Named Agnibaan, this launch vehicle signifies a major leap forward in space technology, boasting significant advantages over conventional methods.

Agnikul Cosmos’ co-founder Srinath Ravichandran highlights the transformative power of 3D-printing technology in rocket engine production. Agnibaan’s engine takes a mere 72 hours to print, compared to the 2-3 months required for traditional manufacturing methods. This drastic reduction in production time translates to faster development cycles and improved efficiency.

Beyond speed, 3D-printing offers substantial cost benefits. The Agnibaan engine is estimated to be one-tenth the price of a conventionally manufactured engine. This dramatic reduction in cost paves the way for more affordable space exploration, opening doors for private companies and research institutions.

Agnibaan represents a significant milestone for India’s space industry. This successful launch demonstrates the nation’s growing prowess in indigenous space technology. The potential for faster, cheaper rocket production paves the way for a more robust and competitive Indian space program.

As the company refines its 3D-printing technology and scales its operations, we can expect to see even more advancements in this exciting field. The future of space exploration looks brighter than ever, thanks to the pioneering efforts of companies like Agnikul Cosmos.

NOTE : Article cannot be reproduced without written permission of idrw.org in any form even for YouTube Videos to avoid Copy right strikes. Websites doing illegal reproductions will get DMCA and Legal Notices.