SOURCE: IDRW.ORG.

The Technology Development Fund (TDF) has issued a call to Indian Micro, Small, and Medium Enterprises (MSMEs) to develop a Fiber Bragg Grating (FBG)-based Structural Health Monitoring (SHM) system. The aim of this initiative is to enhance the structural integrity of various vehicles and systems by continuously monitoring their health throughout their operational lifespan, ensuring both safety and economic efficiency.

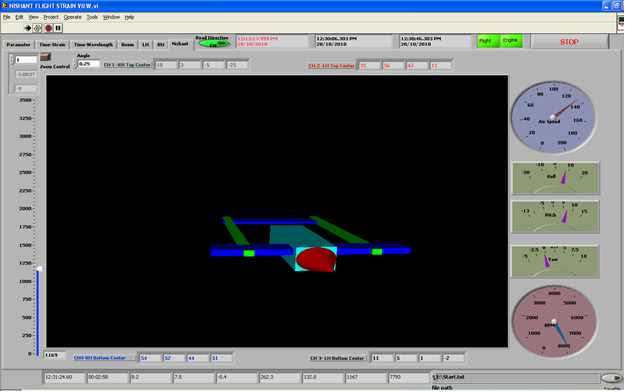

Structural Health Monitoring (SHM) systems are designed to monitor the health of a structure, ensuring its static strength, durability, and damage tolerance during its specified usage period. The primary goal of SHM is to prevent unexpected structural failures, which can pose safety risks and lead to expensive repairs. By having structures equipped with SHM systems, maintenance teams can receive real-time data on the overall health of the structure based on information gathered from built-in sensors and analyzed by SHM algorithms.

One of the key benefits of SHM is its ability to shift from traditional scheduled maintenance routines to a more efficient “Maintenance-on-Demand” system. This concept involves performing maintenance only when necessary, based on the condition of the structure, rather than adhering to pre-set maintenance schedules. This not only reduces costs but also increases the operational lifespan of the structure, ensuring safety and optimal performance.

At the heart of the proposed SHM system are Fiber Bragg Grating (FBG) sensors. FBG sensors have emerged as the ideal candidates for structural health monitoring due to their ability to accurately measure physical parameters such as strain, temperature, and pressure. These fiber optic sensors have been researched and developed for decades and are widely used across industries, from aerospace to civil engineering.

FBG sensors are lightweight, immune to electromagnetic interference, and highly sensitive, making them suitable for monitoring the structural integrity of vehicles, including aircraft, ships, and land vehicles. Their integration into structures provides a “nervous system” that continuously senses, measures, and communicates various environmental and structural parameters.

Key Benefits of FBG-Based SHM Systems

Versatile Application: While initially aimed at vehicles, this SHM system can be extended to infrastructure such as bridges, pipelines, and buildings.

Continuous Monitoring: The system provides real-time data on the health of the structure, enabling maintenance teams to assess conditions frequently and accurately.

Early Damage Detection: By detecting damage early, such as cracks, strain, or pressure fluctuations, FBG sensors can prevent catastrophic failures before they occur.

Cost Efficiency: The “Maintenance-on-Demand” approach reduces the frequency of unnecessary maintenance, saving both time and money.

Lightweight and Non-Intrusive: The installation of FBG sensors adds minimal weight to the structure and does not interfere with its normal operations.

TDF’s call to Indian MSMEs aims to foster the development of indigenous SHM systems, contributing to India’s growing self-reliance in defense and critical infrastructure technologies. The successful development and implementation of an FBG-based SHM system will provide India with an advanced solution for enhancing the safety, reliability, and efficiency of its vehicles and infrastructure.

NOTE : Article cannot be reproduced without written permission of idrw.org in any form even for YouTube Videos to avoid Copy right strikes. Websites doing illegal reproductions will get DMCA and Legal Notices.