SOURCE: RAUNAK KUNDE / NEWS BEAT / IDRW.ORG

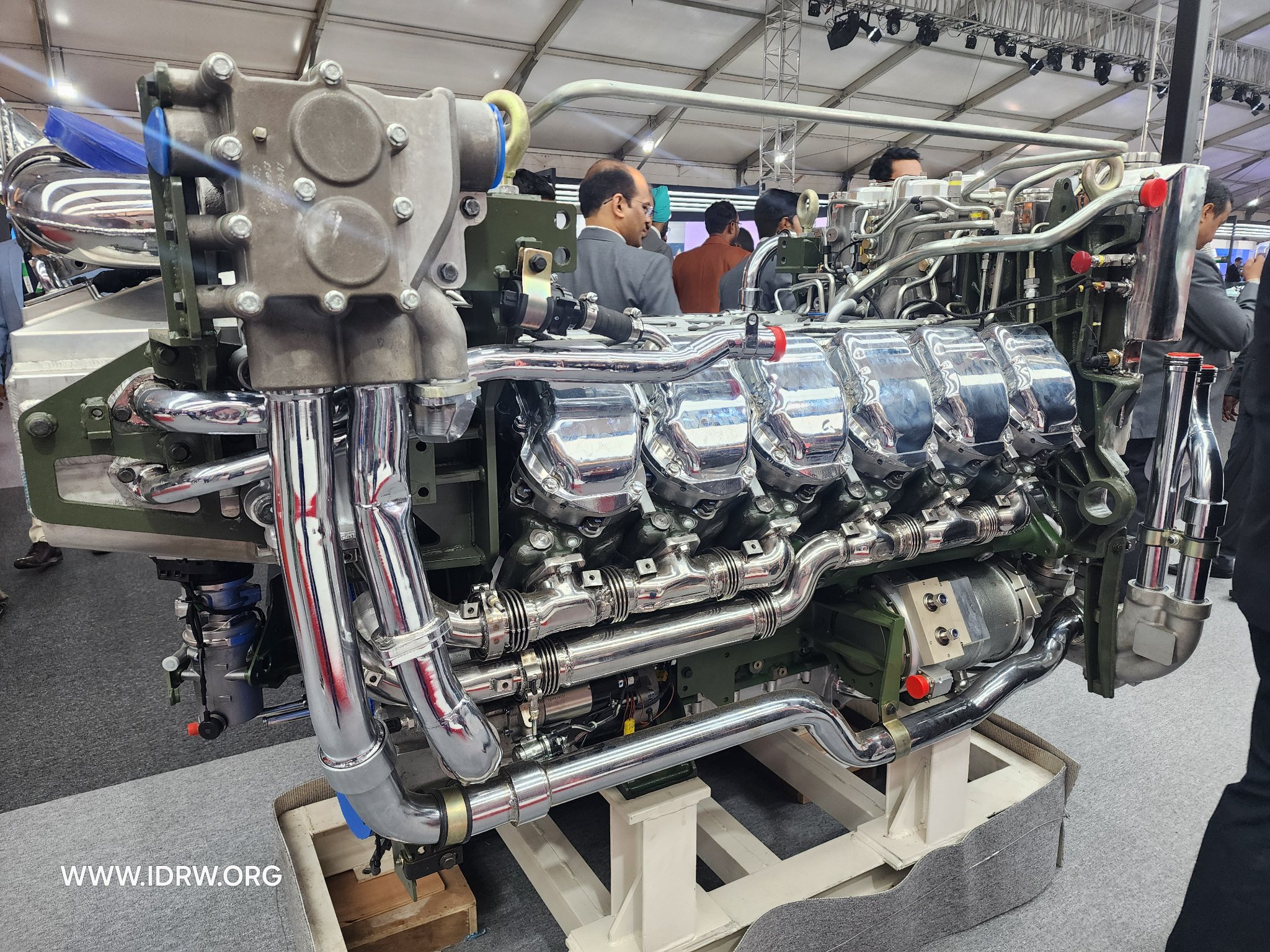

The Defence Research and Development Organisation (DRDO) is making significant strides in indigenous tank propulsion technology with its DATRAN-1500 HP engine, designed for the Futuristic Main Battle Tank (FMBT) and Arjun Mk1A Main Battle Tank (MBT) programs.

In a recent revelation, DRDO officials have disclosed ambitious plans to develop even more powerful engine variants based on the same DATRAN core, incorporating modular design principles to scale up power output if needed.

The DATRAN-1500 HP engine, developed by DRDO’s Combat Vehicles Research and Development Establishment (CVRDE) in collaboration with industry partners like Bharat Earth Movers Limited (BEML), represents a landmark achievement in India’s quest for self-reliance in defence technology.

What sets the DATRAN engine apart is its modular design, a feature that DRDO officials have highlighted as a key enabler for future scalability. According to sources quoted by idrw.org, the engine has been engineered with modular sections, allowing for the integration of new core components to boost its rated power output.

This design philosophy ensures that the DATRAN engine can be adapted to meet varying requirements without necessitating a complete redesign. DRDO officials have indicated that, if operational needs arise, the engine’s power could be increased by 100-300 HP, potentially reaching up to 1800 HP—a capability that aligns with the Indian Army’s vision for heavier, more capable MBTs in the future.

The modular approach to the DATRAN engine’s design is a strategic move by DRDO to future-proof India’s tank propulsion systems. By segmenting the engine into interchangeable core sections, engineers can enhance specific components—such as turbochargers, fuel injection systems, or cooling mechanisms—without overhauling the entire powerplant. This flexibility not only reduces development time and costs for higher-capacity variants but also allows for easier maintenance and upgrades in the field.

The potential to scale up the DATRAN engine to 1800 HP would position it among the most powerful tank engines globally, rivalling systems like the German MTU MB 873 Ka-501 (used in the Leopard 2) or the American Honeywell AGT1500 (used in the M1 Abrams). Such a power increase could support heavier armour, advanced electronics, and additional systems on future MBTs, ensuring they remain competitive against modern threats like advanced anti-tank guided missiles (ATGMs) and loitering munitions.

In addition to scaling up power, DRDO is exploring a hybrid propulsion system for future variants of the DATRAN engine. This hybrid system would combine the internal combustion engine with electric motors, powered by a battery pack, to drive the tank. The concept, still in the proposal stage, aims to introduce a “stealth mode” capability, allowing MBTs to operate silently using battery power for critical missions. This could prove invaluable in scenarios requiring covert movement, such as reconnaissance or surprise attacks, where the noise and thermal signature of a traditional diesel engine might compromise the tank’s position.

The hybrid system would work by enabling the tank to switch between its internal combustion engine for high-power operations (like rapid manoeuvres or combat engagements) and electric motors for low-signature movement. While the electric mode would likely have limited range and speed due to battery constraints, it could provide a tactical edge in specific contexts, such as urban warfare or border skirmishes where stealth and surprise are paramount.

DRDO officials have cautioned that the hybrid system is still in the early stages of conceptualization and will likely emerge several years after the DATRAN-1500 HP engine enters production. Developing a reliable hybrid propulsion system for a 50-tonne-plus MBT poses significant engineering challenges, including battery weight, energy density, and integration with existing drivetrains. However, the potential benefits—reduced detectability, improved fuel efficiency, and enhanced operational flexibility—make this a promising avenue for future research.

NOTE: Article cannot be reproduced without written permission of idrw.org in any form even for YouTube Videos to avoid Copy right strikes. Websites doing illegal reproductions will get DMCA and Legal Notices.